In the realm of HVAC systems, efficiency, reliability, and cost-effectiveness reign supreme. While traditional metal ducting has long been the go-to option, technological advancements have introduced fabric ducting as a worthy alternative. Among the leading providers of fabric ducting solutions stands DuctSox, renowned for its innovation and performance.

The DuctSox Difference

As an essential component of HVAC systems, DuctSox fabric ducting revolutionizes airflow distribution, ensuring unparalleled comfort and efficiency in any environment. DuctSox fabric ducting ensures consistent airflow distribution, eliminating hot and cold spots to enhance comfort in any environment. With minimal pressure drops and turbulence, DuctSox fabric ducting maximizes HVAC system efficiency, resulting in reduced energy consumption and operational costs compared to traditional metal ducting. The cost savings extend to installation, maintenance, and energy usage over time. Precise control of airflow patterns allows for optimal ventilation and temperature regulation tailored to specific needs. Moreover, the lightweight nature of DuctSox fabric ducting simplifies installation, reduces structural support requirements, and saves both time and resources. Its straightforward installation process minimizes labor costs and project timelines.

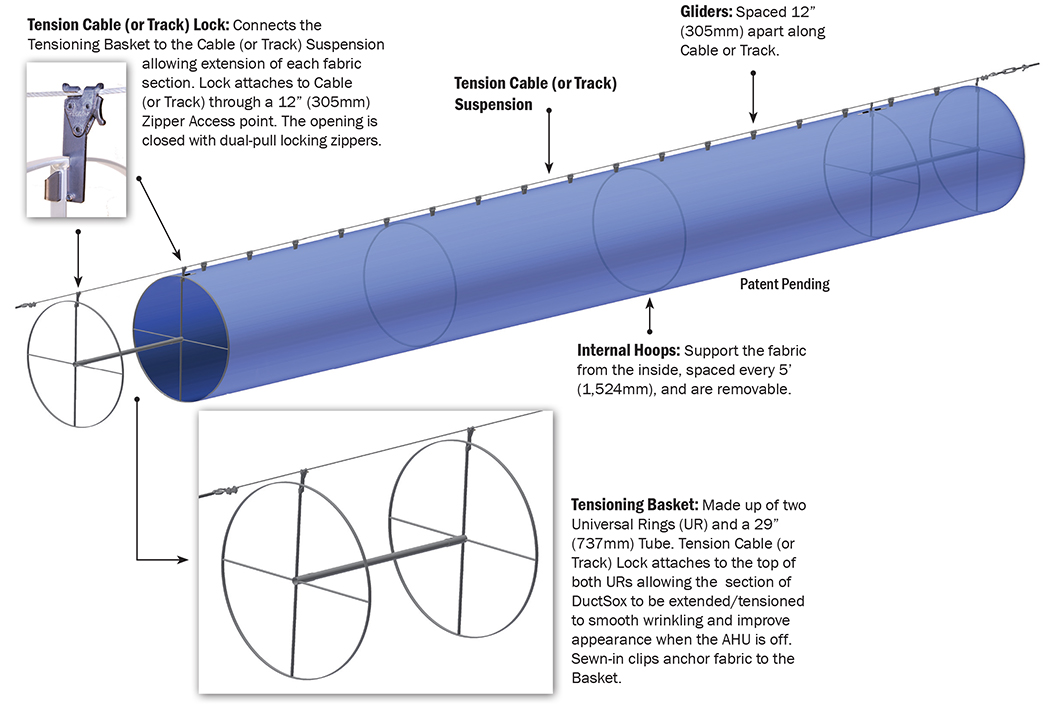

Additionally, DuctSox fabric ducting eliminates condensation issues commonly associated with metal ducting, preserving indoor air quality and preventing moisture-related damage. Available in various colors and fabric options, DuctSox fabric ducting seamlessly integrates with interior design schemes, enhancing the aesthetics of any space. Accommodating variable air volume systems with ease, DuctSox fabric ducting provides consistent airflow regardless of fluctuations in demand. Offering versatility with options for porous and non-porous fabrics, DuctSox fabric ducting caters to specific ventilation requirements. Utilizing internal rings/hoops, DuctSox fabric ducting ensures the duct maintains its shape and retention, optimizing airflow performance. DuctSox fabric ducting stands as a testament to innovation and performance, offering a comprehensive solution that not only optimizes airflow but also enhances the overall functionality and aesthetics of HVAC systems.

Comparing the DuctSox SkeleCore™ FTS, SkeleCore™ Pull-Tight, and Internal Hoop System (IHS)

Among the array of innovative solutions offered by DuctSox, three standout options — the SkeleCore™ FTS, SkeleCore™ Pull-Tight, and Internal Hoop System (IHS) — cater to distinct needs within HVAC systems.

DuctSox SkeleCore™ FTS

The DuctSox SkeleCore™ FTS (Fabric Tensioning System) optimizes airflow performance in HVAC systems. Featuring a unique metal-to-metal direct hang cable method, it ensures safe and durable suspension of fabric ducting. By eliminating disruptive tendencies like motion and noise during AHU start-up, it guarantees a smoother and quieter operation. Tensioning the entire length and circumference of the fabric duct, it promotes uniform airflow distribution and minimizes fabric sag and wrinkling. With fully tensioned fittings and a wide diameter range, the SkeleCore™ FTS offers flexibility and reliability for various HVAC configurations, backed by a generous 20-year warranty. This makes it particularly well-suited for applications where maintaining optimal airflow performance is critical, such as offices, hospitals, schools, hotels, manufacturing plants, warehouses, and cleanrooms.

SkeleCore™ Pull-Tight

The DuctSox SkeleCore™ Pull-Tight system is best suited for applications where precise airflow control and efficiency are paramount. This system enhances airflow control and efficiency in HVAC applications. With a precise 1-row tension cable or track suspension system, it allows for optimal tensioning and uniform airflow distribution within the fabric ducting. By minimizing deflation through circumference tensioning at basket and hoop placement, it ensures consistent airflow performance over time. Available in various diameters up to 60”, it offers versatility for different HVAC configurations and comes with a reliable 15-year warranty. Its capability to enhance airflow control through precise tensioning and minimize deflation ensures consistent air distribution, making it ideal for environments such as commercial kitchens, laboratories, data centers, and server rooms. Additionally, its versatility in accommodating various diameters and its long-term warranty make it a preferred choice for a wide range of HVAC configurations in commercial, industrial, and institutional settings.

Internal Hoop System (IHS)

Each system effectively addresses disruptive tendencies, offering durability and reliability. However, differences in hanging methods, tensioning mechanisms, and warranty coverage allow for tailored solutions based on specific project requirements, priorities, and desired levels of safety and durability.

The DuctSox Internal Hoop System (IHS) is particularly well-suited for applications prioritizing noise reduction, longevity, and consistent airflow performance. Prioritizing noise reduction and longevity, the IHS boasts a longer life expectancy compared to other suspension systems. By minimizing fabric motion and noise at startup, it creates a quieter environment and enhances occupant comfort. Utilizing a 1-row tension cable or track suspension system, it ensures simplified installation and maintenance, making it suitable for environments where ease of installation is crucial, such as retail spaces and educational institutions. With circumference tensioning at hoop placement, the IHS guarantees consistent tension distribution throughout the fabric ducting, minimizing deflation and ensuring optimal airflow performance over time. Available in various diameters up to 60”, it offers flexibility for different HVAC configurations, supported by a solid 10-year warranty. The Internal Hoop System’s blend of noise reduction, durability, ease of installation, and reliable airflow performance renders it an ideal solution across various commercial, institutional, and industrial environments.

Each system effectively addresses disruptive tendencies, offering durability and reliability. However, differences in hanging methods, tensioning mechanisms, and warranty coverage allow for tailored solutions based on specific project requirements, priorities, and desired levels of safety and durability.

To learn more about DuctSox fabric ducting or to learn which solution is best for your application, contact sales@michiganair.com.