As the local Michigan representative for Greenheck HVAC products, we wanted to let you know that we are prepared to help you meet any unique and urgent demands for ventilation products due to the unpredictable developments caused by the COVID-19 virus. Greenheck, our always-responsive manufacturing partner, is dynamically loading its manufacturing operations all over the country to prioritize and service our valuable health care providers who are battling the COVID-19 virus pandemic. Reliable ventilation plays an essential role in the health and safety of our fellow citizens, the producers of food and medical supplies, and our health care and research facilities.

As the local Michigan representative for Greenheck HVAC products, we wanted to let you know that we are prepared to help you meet any unique and urgent demands for ventilation products due to the unpredictable developments caused by the COVID-19 virus. Greenheck, our always-responsive manufacturing partner, is dynamically loading its manufacturing operations all over the country to prioritize and service our valuable health care providers who are battling the COVID-19 virus pandemic. Reliable ventilation plays an essential role in the health and safety of our fellow citizens, the producers of food and medical supplies, and our health care and research facilities.

Working together, with Greenheck, we can respond quickly to any new ventilation equipment required for expanding isolation rooms, patient waiting areas, and other needs. Read about how Greenheck and local representatives across the country have already responded to urgent needs.

Please let us know how we can help you address any ventilation challenges that come up during this crisis. Thank you for your efforts to ensure the continuing health of your communities. We are proud to live in a world that comes together to help each other.

For immediate inquires please email sales@michiganair.com.

Louver Shipped Next Day to Florida Hospital

Louver Shipped Next Day to Florida Hospital

Product: Model EVH-501D, Miami-Dade Qualified & Florida Product, Approved Hurricane Louver

Greenheck Manufacturing Plant: Frankfort, Kentucky

Common Use: Air intake and exhaust while maintaining air performance, hurricane-proof barrier, and architectural integrity

What Happened: Customer placed order through best available, five-day Quick Build (QB) program to help Florida hospital convert patient rooms to isolation rooms for COVID-19 patients. This is a special, Miami-Dade Qualified Hurricane protection louver. The hospital required a two-day turnaround. Greenheck manufactured in one day at the Frankfort, KY plant and shipped Next Day Air to install the following day.

Customer Comment: “Many hospitals in our area need to convert patient rooms to isolation rooms. Greenheck’s Quick Delivery has enabled us to support those efforts. In times like these, we all need to pull together for the greater good.”

More Lab Exhaust Equipment Needed in Virginia

More Lab Exhaust Equipment Needed in Virginia

Product: Model Vektor-MH, 3×1 Laboratory Exhaust System

Greenheck Manufacturing Plant: Schofield, Wisconsin

Common Use: Laboratory / Isolation / Hazardous Fume Exhaust

What Happened: A new nine-floor wing was being constructed on an existing hospital in Virginia. The original plans called for one isolation floor. With the drastic increase in demand for isolation rooms to accommodate COVID-19 patients, two more floors are being converted into isolation areas. Normally, there is an 8-week lead time for this type of specialty laboratory exhaust equipment, and no Quick Build options are available. However, Greenheck’s local rep worked with Greenheck engineering in Schofield, WI to find the right products to meet the need within an expedited time frame of 3-weeks.

Customer Comment: “We were directed in early March, because of this virus outbreak, to convert the Level-3 ICU east wing to negative pressurization isolation rooms with the capability to see patients by 4/3/2020. The quick construction and turnaround of Greenheck will allow the hospital to be prepared for this pandemic outbreak.”

Utility Set Fan for COVID-19 Patients Overflow

Utility Set Fan for COVID-19 Patients Overflow

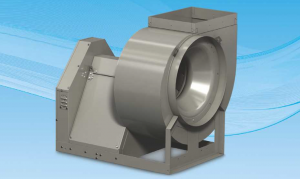

Product: Model USF, Utility Set Fan

Greenheck Manufacturing Plant: Shelby, North Carolina

Common Use: Supply air or exhaust for room pressurization

What Happened: A hospital in Wisconsin needed to convert an existing burn unit into a COVID-19 patient overflow space. Airflow was critically important for this conversion, and the hospital requested expedited manufacturing of a utility fan. The unit shipped within 7-days from Greenheck’s North Carolina operations.

Customer Comment: “In these crucial times with so much uncertainty, Greenheck has played a vital role in helping contractors quickly build negative pressure rooms for hospitals treating the COVID-19 virus.”

Medical Supplier Needs Damper

Medical Supplier Needs Damper

Product: VCD-23, Volume Control Damper

Greenheck Manufacturing Plant: Mosinee, Wisconsin

Common Use: Steady control and balance of airflow and pressurization for critical areas

What Happened: Increased demand for hand sanitizer due to the COVID-19 crisis required a large national medical supplier to immediately increase production. To expand hand sanitizer output as quickly as possible, they needed a crucial damper and other ventilation products. The order was placed on a Wednesday at 3:46 PM. Recognizing the urgency, Greenheck’s damper team worked overnight at the plant in Mosinee, Wisconsin and shipped the finished damper to the customer at 10:30 AM the next day.

Customer Comment: “Greenheck and its local rep helped get our new production line for hand sanitizer up and running in the midst of the COVID-19 crisis. It was essential that the fans, dampers, and make-up air units be manufactured and delivered quickly in order to keep this essential business operational. Thank you to responding to the needs of all aspects of the health case industry.”

Greenheck manufactures air movement, control, and conditioning products including fans, dampers, louvers, laboratory and fume exhaust, kitchen ventilation systems, energy recovery ventilators, dedicated outdoor air systems, make-up air systems, duct heaters, and HVAC coils.